YONGDA provides plastics solutions.

Plastic Injection & Mold & Solutions:

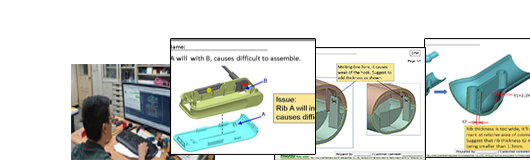

DFM @2D/3D @Part (& Design Review)

DFM @2D/3D @Part (& Design Review)

Considering mechanism, tooling, injection, machine, manufacture, production, and their economy, we have to take care good to make product being produced fluently, and both with customer get advantage. Design review / Proposal feedback by 3D model if necessary, to let you understand what's the issue clearly.

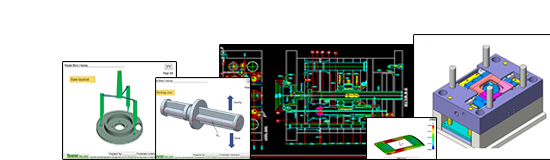

Mold Design (& DFM @Mold / Injection)

Mold Design (& DFM @Mold / Injection)

According to the DFM, tooling designed will be more safe, correct, faster, and perfect. Then part will be produced fluently. More details see "Mold design / Mold DFM" page.

Mold / Tooling Manufacture

Mold / Tooling Manufacture

Specialize in single-shot injection mold, double-shot injection mold, IMD mold, soft tooling for test. More details see "Mold Manufacture" page.

Plastic Injection

Plastic Injection

With good mold which follows DFM mentioned above, basicly, there will be no big issue in injection. Machines show on "Plastics Injection" relative page.