YONGDA Enterprise Co., Ltd.

DFM @2D/3D @Part (& Design Review)

DFM @2D/3D @Part (& Design Review)

YONGDA's knowledgeable engineers assist customer in mechanical design-review to reduce faults in advance, either it’s single part or assembly.

Considering mechanism, tooling, injection, machine, manufacture, production, and their economy, we have to take care good to make product being produced fluently, and both with customer get advantage.

Design review / Proposal feedback by 3D model if necessary, to let you know what's the issue clearly.

DFM support helps design being good, makes parts manufactureable, makes assembly function reasonable and suitable. Design review helps issues to be found, solved in advance, to avoid problems occured during trial-run & mass-procuction. Design review also provides you proposal, assists to solve those latent problems, provides you other method or procedure, make the design better.

YONGDA, provides plastics solutions, pleased to have good communication with costomers, helps design, helps proposal, and feedback, also can modify drawings directly to help partners understand issues, make issues being solved in advance, and let customer konws what we concern about the part which is going to be manufactured.

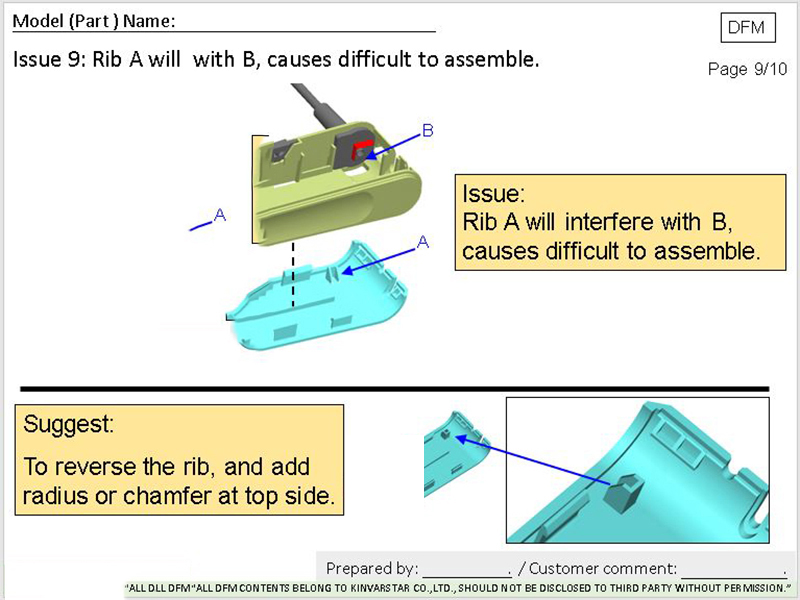

Assembly review :

When desingning, designer should consider cosmetics, material, strength, drop, weigth, thickness, assembled easily, etc.

Designer might neglect some features at times, and then it'll cause mold weak, part weak , or mold difficult to be made, even can't be made, or can't be formed, or occurs other defects.

Our knowledgeable engineers contribute parts being good, help review drawings, go through considering the mechanism, material, mold struture, injection, then suggest something better.

For example:

Hook's interference is too much, it is assembled easy and secure, but can't disassemble.

Gap between two parts is tiny, the part may not be formed actully, because injection can't reach precision requested, and will cause high yield loss.

Gap between two parts is too big, the assembly will crunch. It'll also cause tooling modified several times. We might suggest how's the gap size, or adding rib features to offset it.

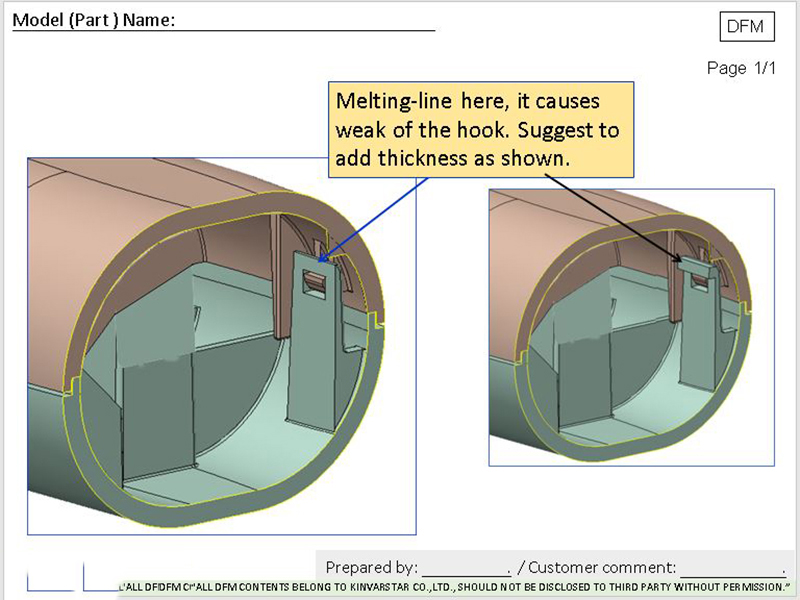

Melting-line generated at top of the hook shown as picture "Assembly review & proposal -b", it will cause the hook strength weak, surely it's a latent problem. The solution is to add thickness shown as picture.

Two parts assembled not only hooks, but also they need some ribs to hold each other. Thus the ribs make assembly being stable, and easy to assemble. It also help parts to be more rigid.

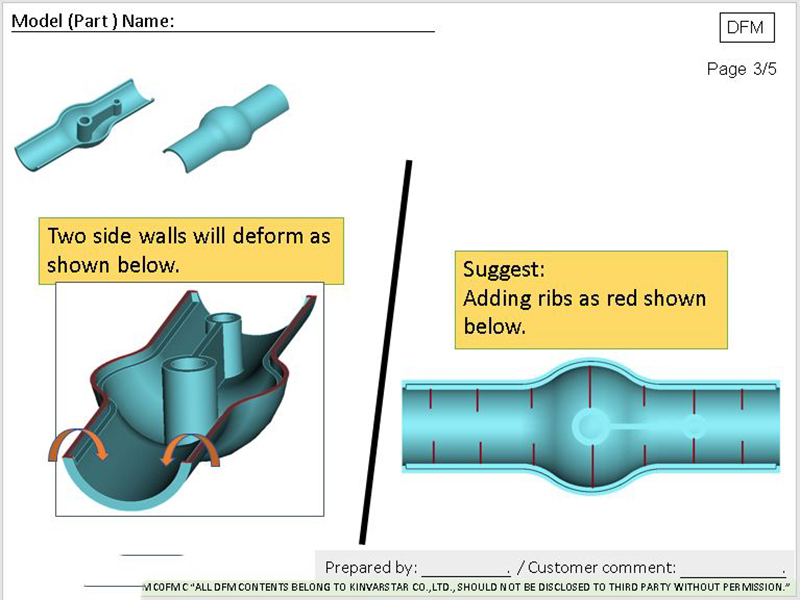

Part review & DFM :

Generally, when designing a part, we should consider about its tooling, we want mold to be workable. We don't want mold structure to be complex, because complex structure has risk for mold lifetime. But anyway, product design is first, though it'll be a complex mold structure, so at this time we just consider if its mold is workable.

As a product designer, when designing a part, we also consider:

a, Parting-line location, we don't want it apeared on cosmetic.

b, Draft angle. Insufficient draft angle will cause scratch.

c, Thickness should be even / everage as possible, for resin fill in smoothly when injection.

d, Strength and rigid. Sometimes we add ribs to rigid the part.

e, Gate location.

With thinking above, design become skillful, it takes more thoughts and experience. Taking care above, the quality of injection will be more stable and easy to be control.

We do effort to help customer to review part, and feedback, this is DFM.

Sometimes, thickness is too thin, it can harly be formed when injection.

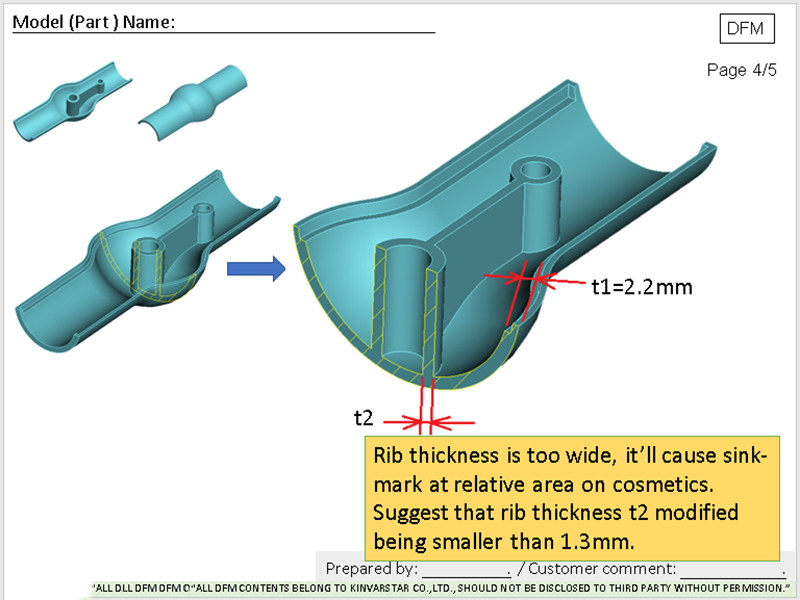

Sometimes, thickness is too thick, the cosmetics will has sink-mark.

Sometimes, thickness isn't even / average, it'll be difficult to controll the precision.

The part need be modified the structrue to improve.

Sometimes, the structure of part / assembly is weak, it can't pass drop test.